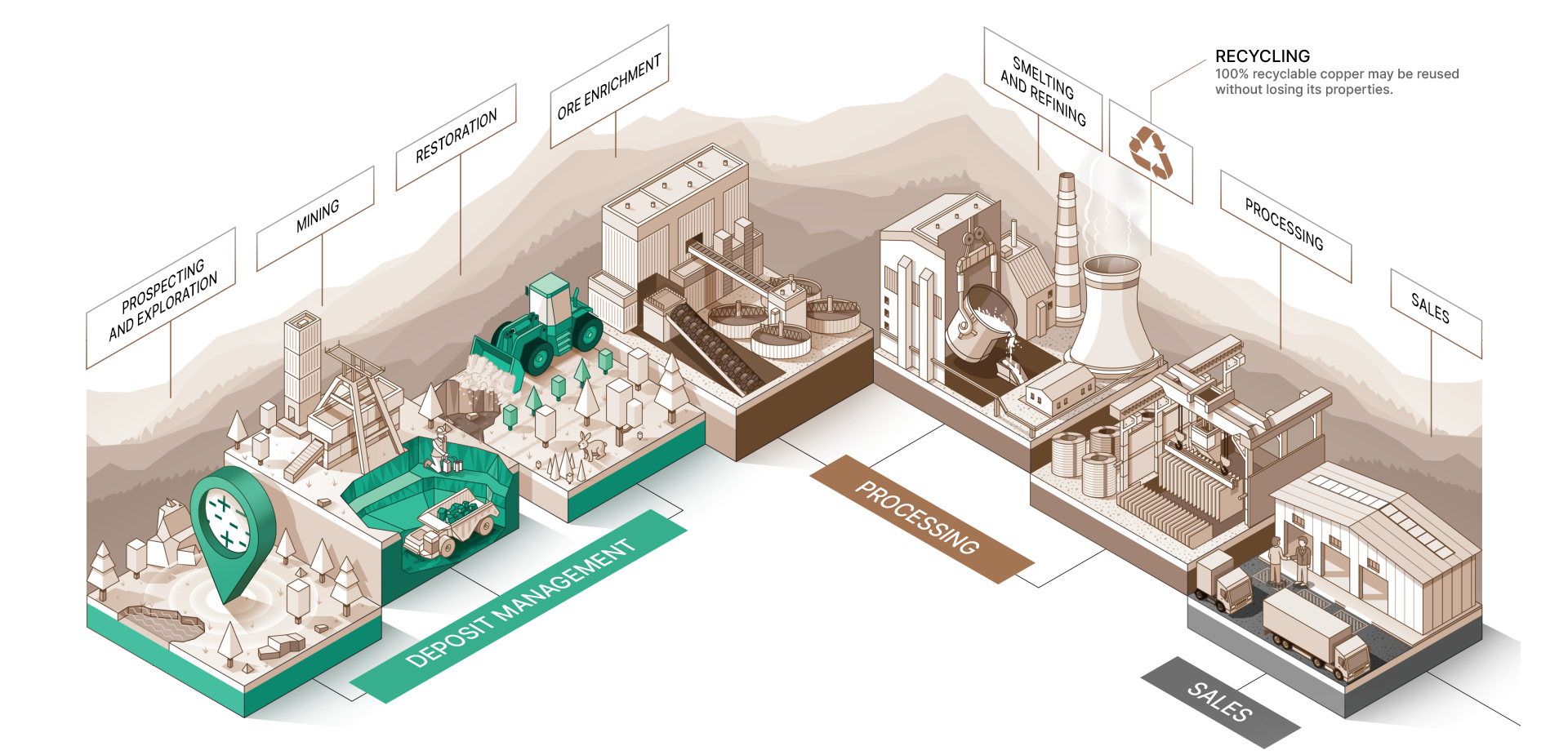

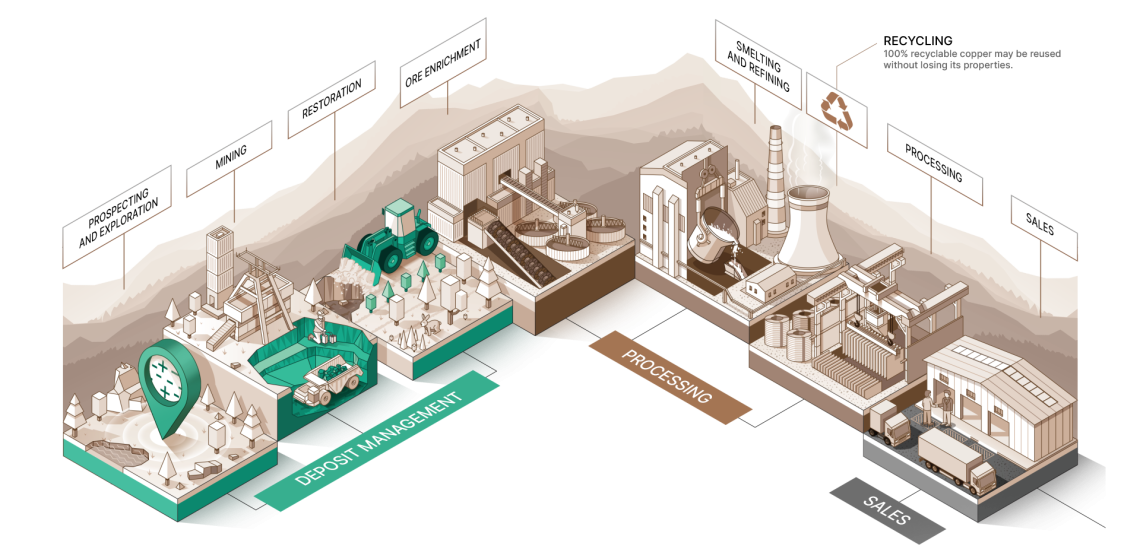

Copper smelters produce electrolytic copper based on their own concentrates and international inputs (copper concentrates, copper scrap, blister copper).

The Legnica Copper Smelter and Refinery uses a multi-stage process whose main stages include: preparation of the charge material, its reduction smelting in shaft furnaces to the form of matte copper, conversion to the form of blister copper with approx. 98.5% copper content; fire refining in anode furnaces to produce anodes of 99.2% copper content; and electrorefining. The final product is electrolytic copper cathodes with 99.99% copper content.

The Głogów Copper Smelter and Refinery uses a single-stage technology of processing concentrate in flash furnaces, based on a license from the Finnish company Outokumpu. The dried concentrate with a moisture content of 0.3% H2O is smelted in a flash furnace to form blister copper with a Cu content of approx. 98.6%, which undergoes fire refining in anode furnaces. The slurry slag containing about 12%-14% copper is sent for decopperization in an electric furnace, and the resulting CuPbFe alloy is sent to converters, from which copper with a purity of 98.5% also goes for refining in anode furnaces. The anodes obtained in the process of fire refining are subjected to the process of electrorefining whose end product is electrolytic copper in the form of cathodes with the content of 99.99% of Cu.

Approximately 49% of the electrolytic copper produced by the smelters of KGHM Polska Miedź S.A. is processed in the rolling mill of the Cedynia Copper Wire Rod Plant, where copper wire rod is produced by continuous melting, casting and rolling, and oxygen-free copper rod and low-alloy oxygen-free copper rod with silver, is made using UPCAST technology.

Sludge generated in the electrorefining processes at KGHM smelters contains precious metals and is a raw material at the Precious Metal Plant at the Głogów Copper Smelter and Refinery for the production of: refined silver, gold, palladium-platinum concentrate and selenium. In turn, the electrolyte withdrawn from the tankhouse circuit, after decopperization, is directed to the production of crude nickel sulphate.

Lead-bearing dust and sludge from the dust removal from process gases of all smelters are smelted together with decopperized converter slag from the slurry line in Dörschl furnaces in the Lead Division of the Głogów Copper Smelter and Refinery to form crude lead with 99.3% Pb content. Raw lead undergoes a refining process at the Legnica Copper Smelter and Refinery, which results in a final product in the form of refined lead with a 99.85% Pb content.